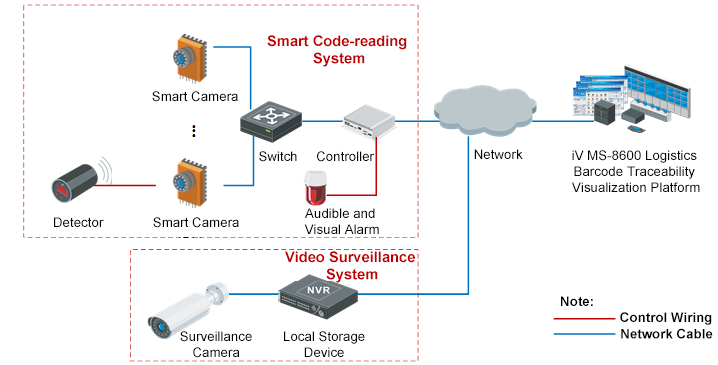

Hikvision Traceability Visualization Management System for Logistics consists of an smart code-reading system, a video surveillance system and a video management platform, offering automatic code reading, parcel tracking, etc.

Hikvision Traceability Visualization Management System for Logistics is closely integrated with the smart code-reading system and the iVMS-8600 platform, and can be applied in assembly lines, warehousing centers, transfer stations and distribution centers. In the stationary-mounted system, the smart code reading part performs deep data mining by acquiring, recognizing, analyzing and managing numerical codes, which significantly improves the efficiency and accuracy of code reading. The security IPC performs real-time video recording for the packages. The recording data is then attached to the Hikvision iVMS-8600 platform and linked to the data in the iVMS-8600 platform through the smart code-reading system. With this process, functions such as smart video retrieval, quick problematic package backtracking, staff management, express package management are enabled.

By focusing on complete management of people, vehicles and goods in the express logistics business, it can realize many core functions such as fast smart control, easy task management, accurate real-time visualization positioning and simple bar code scanning, allowing the company to achieve the goal of “safety and high efficiency”.

For the warehousing, transportation and other core links of general logistics enterprises, the logistics traceability visualization management system offers many vital functions such as vehicle location, monitoring and alarming, vehicle scheduling, warehousing supervision, inventory management, and video surveillance, making it a cost-effective integrated management system specially designed for the enterprises.

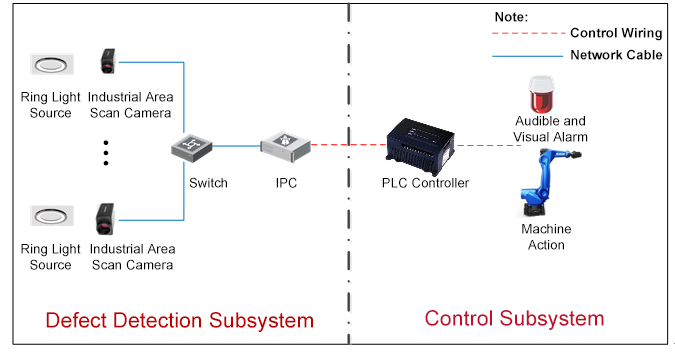

Hikvision logistics sensing system adopts fixed scan mode to achieve the collection, identification, management and analysis of the digital codes on the package, greatly improving the barcode processing speed and accuracy, and industry-specific business features such as package tracking record and data cloud connectivity to facilitate the integration of things. The system consists of logistics sensing system, transmission system and back-end system.

Logistics sensing system:Includes trigger, code reading and image acquisition. The system can output the standard coding format according to the communication protocol and expand the volume measurement module based on specific user demands to realize the fast volume measurement.

Transmission system:The industrial switch is used to carry out reasonable match according to the on-site conditions to ensure the stable and efficient transmission of data.

Back-end system:Third-party processing software, machine and audible and visual alarm for data management and results feedback after code reading.

Copyright ©2022 Robonetics | All rights reserved..